Custom Ceramic Parts

3DCeram Stereolithography (SLA) Technology for technical ceramics.

For more than 15 years the company has developed a know-how in 3D printing, and offers its unique scientific expertise in:

• Mastering SLA laser 3D printing technology

• A process to manufacture ceramic parts

• Off the shelf and bespoke ceramic slurries developed by 3DCeram

Link Free; 3D printing without support

Top-down stereolithography enables technology that can print without supports. The tray moves down as the part itself is built from the bottom-up. 3DCeram is able produce consistent parts with high precision and fine details.

The feeding of the printing material is done by a printing material is fed into a cartridge which is simply filled at the beginning of the printing cycle. It is possible to re-fill the cartridge during the printing cycle.

C100 EASY LAB

The freedom to develop your own process. The C100 is dedicated to R&D development and opens opportunities to;

• Develop materials with a low quantity of material

• Build Platform - 100 x 100 x 150 mm

• Quality design and manufacture

• Print parts to show case

• User friendly

• Open parameters

• Stereolithography laser

• Free link support technology

• Controlled quantity of printed ceramic slurry

• Accessible for persons with reduced mobility

• Start a printing run with only 60 mL of ceramic formulation

• Cartridge of 180 mL, 360 mL, 600 mL or 920 mL available

• Optional: Pressure tank (1,5 L)

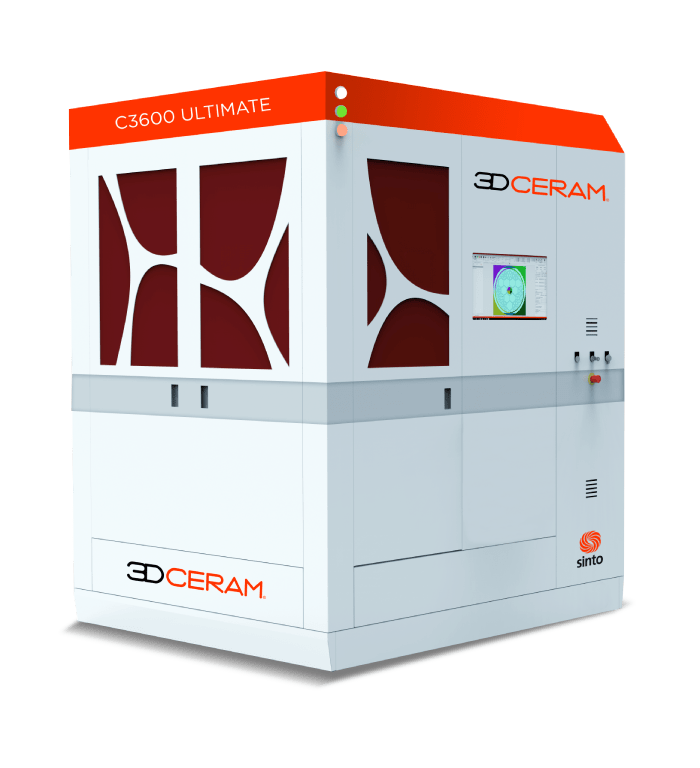

C3600 ULTIMATE

C3600 offers a solution for mass production

• For mass production and printing of big parts

• Scale up from C100 EASY

• Build platform : 600 x 600 x 300 mm

• Free link support technology

• Reduced unit part price

• Reduced cleaning time

• Well adapted to serial printing

C900 Flex

The C900 was the first printer developed by 3DCeram and benefits of 15 years of know-how and optimization.

• Print large functional parts or small series

• Ceramic printed parts have the same properties as those produced in conventional ways (moulding, machining and injection)

• Open parameters

• 3 sizes of building platform : 100 x 300 mm, 200 x 300 mm and 300 x 300 mm

• Free link technology

• SAM (Small Amount of Material) optional: launch a fast printing run with only 100 mL of slurry.